Mobile Equipment Proximity Detection Sensor

Download Selecting the right Mobile Equipment Proximity Detection system for your business

APPLICATIONS

Construction, Scrap Metal, Mining:

To protect workers in high-risk zones with large machinery.

Warehouse and Industrial Settings:

Where forklifts and other vehicles operate in close proximity to people.

Mobile Equipment Proximity Detection

Mobile Equipment Proximity Detection is a safety technology designed to prevent collisions between moving equipment and other machines, structures, or obstacles. This system is widely used in environments such as construction sites, recycling yards, ports, warehouses, and mining operations—locations where large vehicles and heavy machinery must often operate in tight spaces with limited visibility. Its primary goal is to reduce equipment-to-equipment accidents, protect infrastructure, and increase operator awareness of potential hazards in their immediate surroundings.

System Capabilities and Range

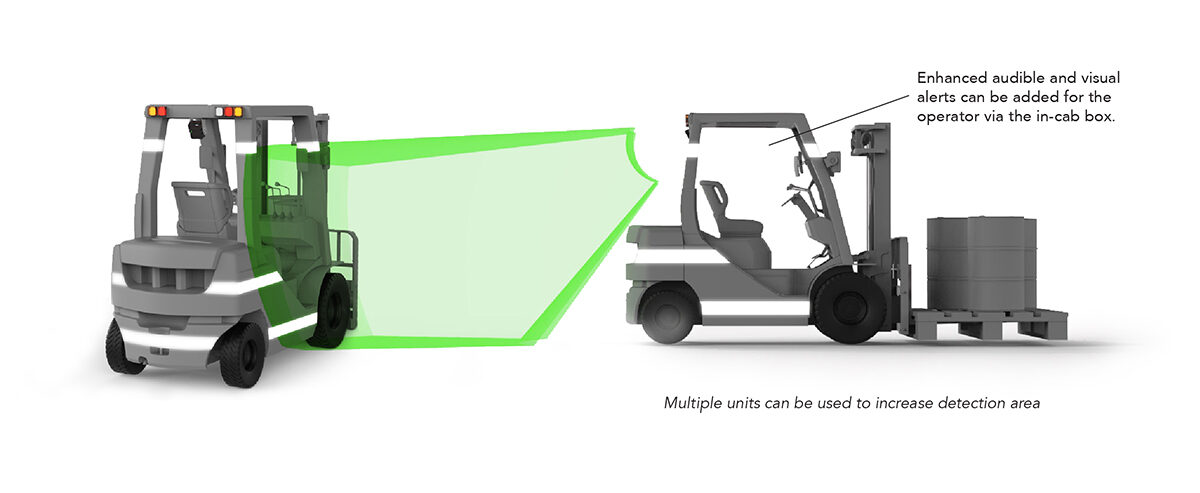

Modern systems feature flexible detection zones that can be customized to different vehicles and site conditions. Depending on the setup, detection ranges can extend from short-distance alerts for confined indoor operations to long-range detection suitable for haul trucks, loaders, and mobile cranes.

Key Components and Functionality:

Sensors and Detection Technology

- Utilizes radar, UWB (Ultra-Wideband), or LiDAR sensors to monitor blind spots and surrounding zones.

- Multi-zone detection can distinguish between close, caution, and danger areas for more precise alerts.

- Works effectively in low-light, dusty, or noisy environments where cameras or mirrors may not provide reliable visibility.

Alert Mechanisms

- Real-time collision alerts provided directly to equipment operators via in-cab display units.

- Audible alarms and visual indicators (lights, warning beacons) warn both operators and nearby crews.

- Systems can integrate with telematics to log near-miss data and generate safety reports.

Positive Behavioral Changes

Promotes safer driving habits by reminding operators to remain aware of blind spots and nearby equipment.

Encourages equipment operators to slow down in high-traffic areas and approach intersections with greater caution.

Builds a culture of proactive hazard awareness across teams that operate multiple machines in the same work zone.

Reduction in Downtime and Costs

- Fewer accidents mean reduced repair costs, fewer insurance claims, and less time lost to investigations.

- Enhances productivity by keeping equipment operational and avoiding workflow disruptions.

- Supports lower OSHA incident rates, which can reduce insurance premiums and regulatory fines.

Optimized Operations and Efficiency

- Detection systems allow operators to work with greater confidence in high-traffic areas.

- Enables smoother coordination between multiple machines on busy job sites.

- Reduces stress for operators, allowing them to focus more on task efficiency and less on constantly scanning blind spots.

Mobile Equipment Proximity Detection Key Benefits

Improved Safety for Equipment Operators and Surroundings

- Significantly reduces the risk of pedestrian-related accidents in industrial settings such as warehouses, manufacturing plants, and heavy industrial applications.

- Real-time alerts enhance operator awareness, allowing quick reaction times to prevent potential collisions.

- Helps protect personnel and assets by focusing on human detection, stripped equipment and infrastructure, eliminating unnecessary distractions from false alerts caused by objects or materials.

Reduction in Injuries, Operational Downtime, and Lower OSHA incident rate

Fewer workplace injuries mean lower medical costs, fewer worker compensation claims, and enhanced productivity.

Minimizes downtime associated with accident investigations, equipment repairs, and legal matters.

Enhances the company’s safety record, leading to improved worker morale, retention, and lower insurance premiums. (Link to Lower OSHA Incident Rate page under “Benefits”)

Optimized Equipment Operation and Workflow Efficiency

- Reduces cognitive overload by allowing operators to focus on tasks instead of constantly scanning for pedestrians.

- Streamlines material handling by ensuring safer and more predictable movement of workers and machinery.

- Enhances navigation in tight spaces or high-traffic zones, reducing operational risks and improving workflow.

Workers actively learn to keep away from the dangers of mobile equipment

With infrared-based pedestrian detection, organizations can prioritize worker safety while improving operational efficiency, making it an ideal solution for industries where mobile equipment and personnel interact frequently.

Companies using the SEEN safety system include:

Member Associations

Let's Connect

To learn more or connect with us, please click below…